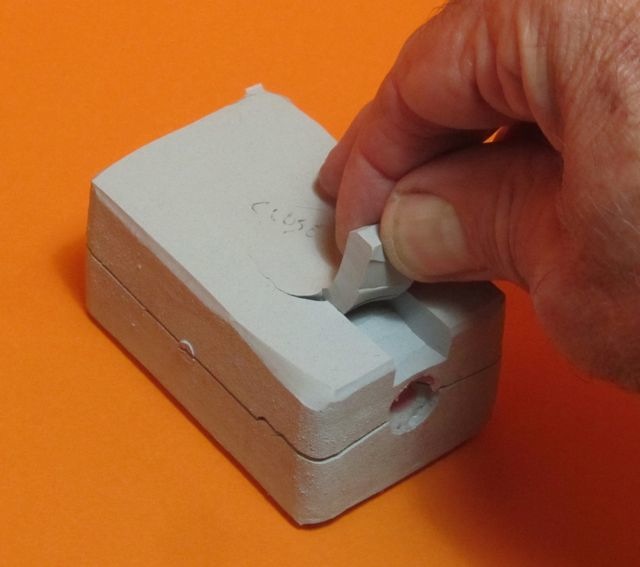

This ring mold is made with Zero-D Products HT40 and HT55 silicone mold rubber. This rubber has tiny metal flakes in it to increase its ability to conduct heat. This allows for quicker cooling and facilitates quicker injection/extraction cycles for the waxes. This first image shows the outside of the 1 7/8 x 2 7/8 x 1 3/8 heat cured mold. The mold has already been cut. Note the seam around the edge, plus the seam around the edge of the plug.

HT40 has a listed shrinkage of 1.8%. HT55 has a listed shrinkage of 1.6%. I wonder if the slightly different shrinkages causes the seams to open. It does not seem to make any difference when the mold is clamped shut - the seams disappear then.

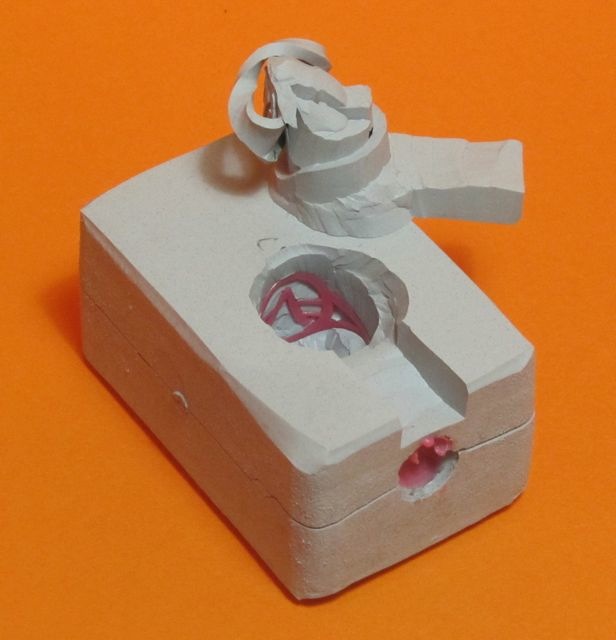

The next three images illustrate the removal of the plug from the mold. I use this mold style when I have a lighter weight ring that will be warped by over eager extraction of the wax. That is, even if the wax is still a little soft because I did not wait long enough for it to cool, this mold cutting style will allow me to see the wax without warping it.

Note the plug between my thumb and index finger. Just below that is a confusing jumble of the plug that fits inside the ring. You can just see the pink wax in the shadow of the plug.

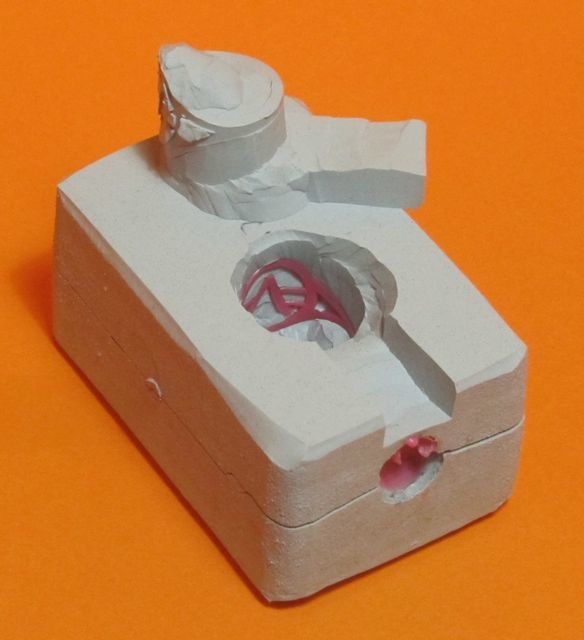

Plug is sitting upside down on top of mold. The loop that is off to the left of the plug is purposeful. That loop allows the mold to be extracted from the wax without warping the wax, even if the wax is still somewhat soft.

This image shows the loop replaced onto the plug. Note the faint seam visible between the loop and plug on the right inside edge of the plug.

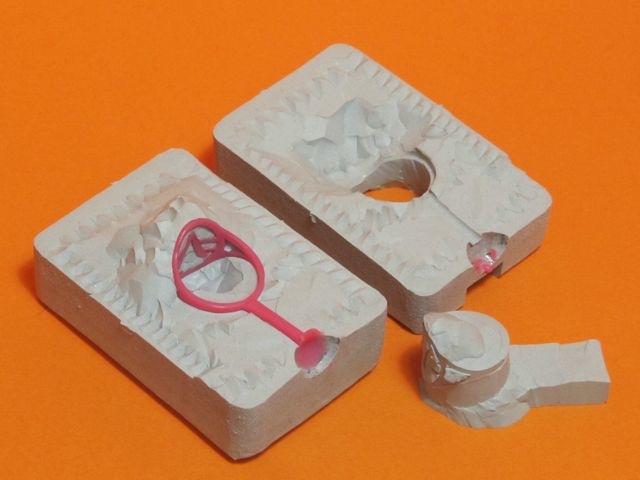

The two halves of the mold almost fall apart once the plug has been removed.

The wax removed from the mold.

If you like this article and would like to see a video of this cutting method, please drop me an email. If there is enough interest, I'll shoot the video and post it.