I was told at the beginning of my career to build in 8 to 12% shrinkage in my wax carved models to make the finished jewelry turn out the right size. How do we use the 4.0 to 0.0 % shrinkage figures we are given by the mold compound suppliers? Is the shrinkage consistent from a small mold to a large mold, a small model to a large model, from one red mold compound to the next red mold compound?

How do we compensate for this shrinkage? What is the conversion factor from model to mold for a given compound? Never mind how much the wax shrinks, the investment, nor the cast metal, nor the abrasive finishing processes. This is about shrinkage in mold compounds.

Method:

I test and compare two methods for determining shrinkage in the materials. One is using a single linear dimension in the mold, the other was an average of two dimensions at right angles to each other on the mold. I test compounds cured at the recommended vulcanizing temperature, and then at higher, or 'push cure' temperatures. I will also be testing RTV (room temperature curing) molds and compare them to the same RTV compounds cured at the manufacturers' recommended 'push-cure' temperatures.

I expect to answer the question: "Is the shrinkage in a mold material different when it is 'push cured'?

First up is Rio Ditto 2. It is a great, firm, RTV compound that push cures in a couple of hours at 300F. Or, you could wait 16 to 24 hours for it to reach full hardness at room temperature. Here is an image of the ruler I embedded in my mold:

We are looking down into the top of the mold. The ruler is taped to the side of the mold frame. Green wax model is in the center of the mold frame. I like to use masking tape to hold the glass sides on the aluminum mold frame.

Results on this test will be available on the new shrinkage data spreadsheet soon.

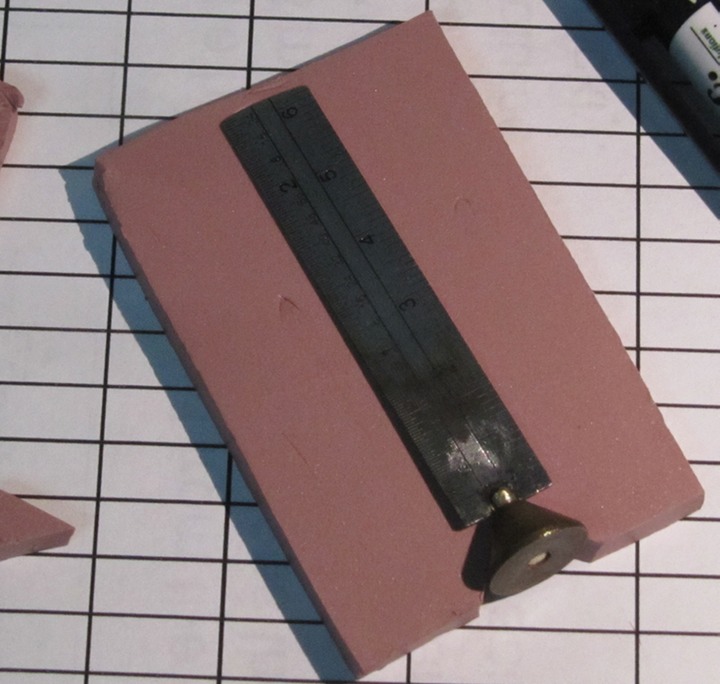

Here is an image of my first test of a heat cured silicone compound. I used Zero-D Products 'Zeroshrink'. It shows a section of stainless steel ruler on the mold compound. I'll vulcanize the mold and compare the shrinkage percentage I get off the length of ruler inside the mold to the shrinkage percentage I measure on the outside of the mold. I've always wondered how Castaldo and Zero-D measurement methods compare. :-)